During the operation of power plant boilers, impurities such as dust and soot gradually accumulate on the heating surface due to the combustion of fuel and various complex physical and chemical reactions. The accumulation of these impurities will seriously affect the heat transfer efficiency of the boiler, leading to energy waste and increased operating costs. At the same time, it may also cause local overheating, posing a threat to the safe operation of the boiler. The main function of the soot blower is to remove these impurities from the heating surface of the boiler. It transfers energy such as compressed air, steam, or sound waves to the heating surface of the boiler in a specific way, causing accumulated impurities to loosen and fall off, thereby maintaining the cleanliness of the heating surface and ensuring that the boiler is always in a good heat transfer state.

1. Significantly improved the thermal efficiency of the boiler: By removing the accumulated ash on the heating surface, the soot blower can significantly enhance the heat transfer efficiency of the boiler, thereby improving the power generation efficiency of the power plant. According to relevant data, soot blowers can improve thermal efficiency by 3% to 5%.

2. The soot blower can also reduce the maintenance cost of the boiler: ash accumulation and slagging can lead to increased wear and tear on the heating surface of the boiler, shortening the service life of the equipment. Regular cleaning of the soot blower can reduce this wear and extend the service life of the equipment, thereby reducing the maintenance cost of the boiler.

3. Blowers can also reduce environmental pollution: if the smoke and exhaust gases generated by boiler combustion are not effectively treated, they can cause serious pollution to the environment. The use of soot blowers can reduce the emission of smoke and exhaust gas, which helps protect the environment and human health.

The application of the soot blower from Hubei Huaxing Machinery Technology Co., Ltd. in the power plant industry has broad prospects and significant importance. By selecting the appropriate type of soot blower and cleaning solution, the problem of ash accumulation in power plant operation can be effectively solved, ensuring the normal operation of equipment and improving production efficiency.

Semi-retractable soot blower

Working speed: Semi-retractable soot blower

Working pressure:≤2Mpa

Request Product details

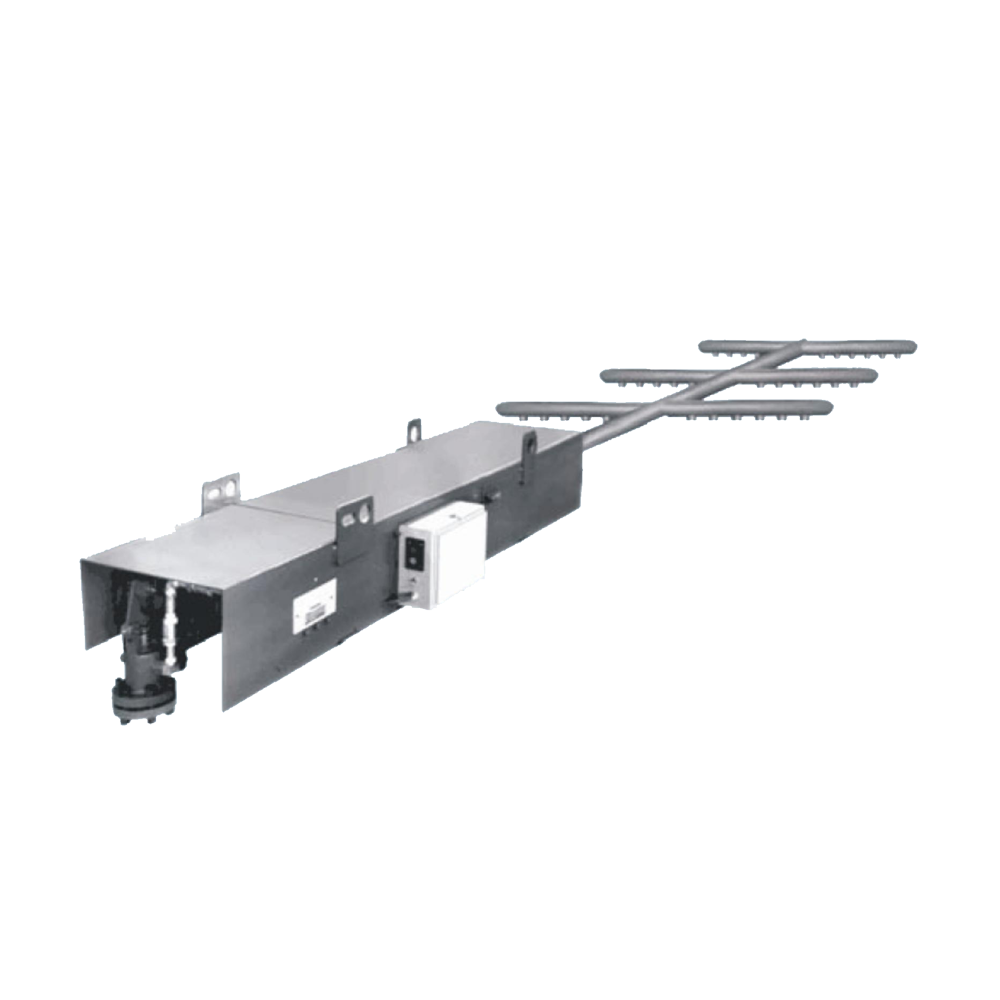

Air preheater soot blower

Working speed: Air preheater soot blower

Working pressure:~1.5Mpa

Request Product details

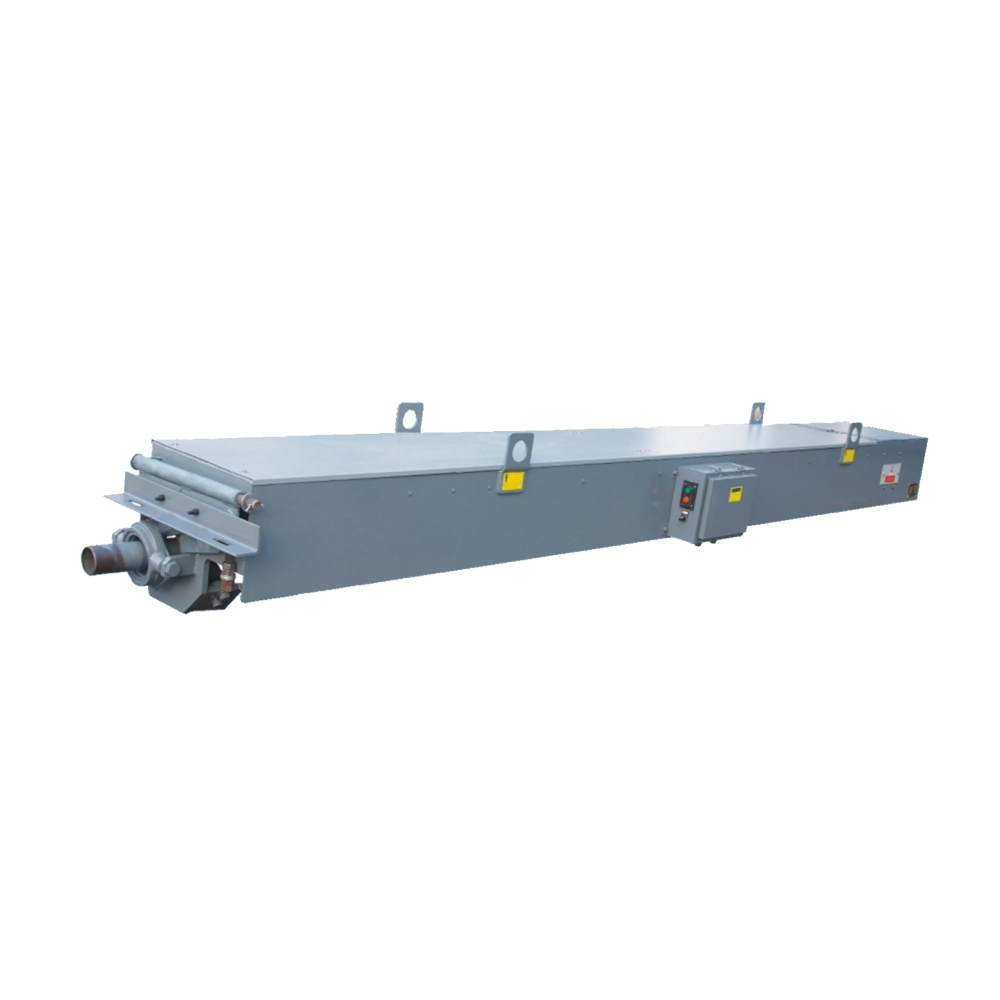

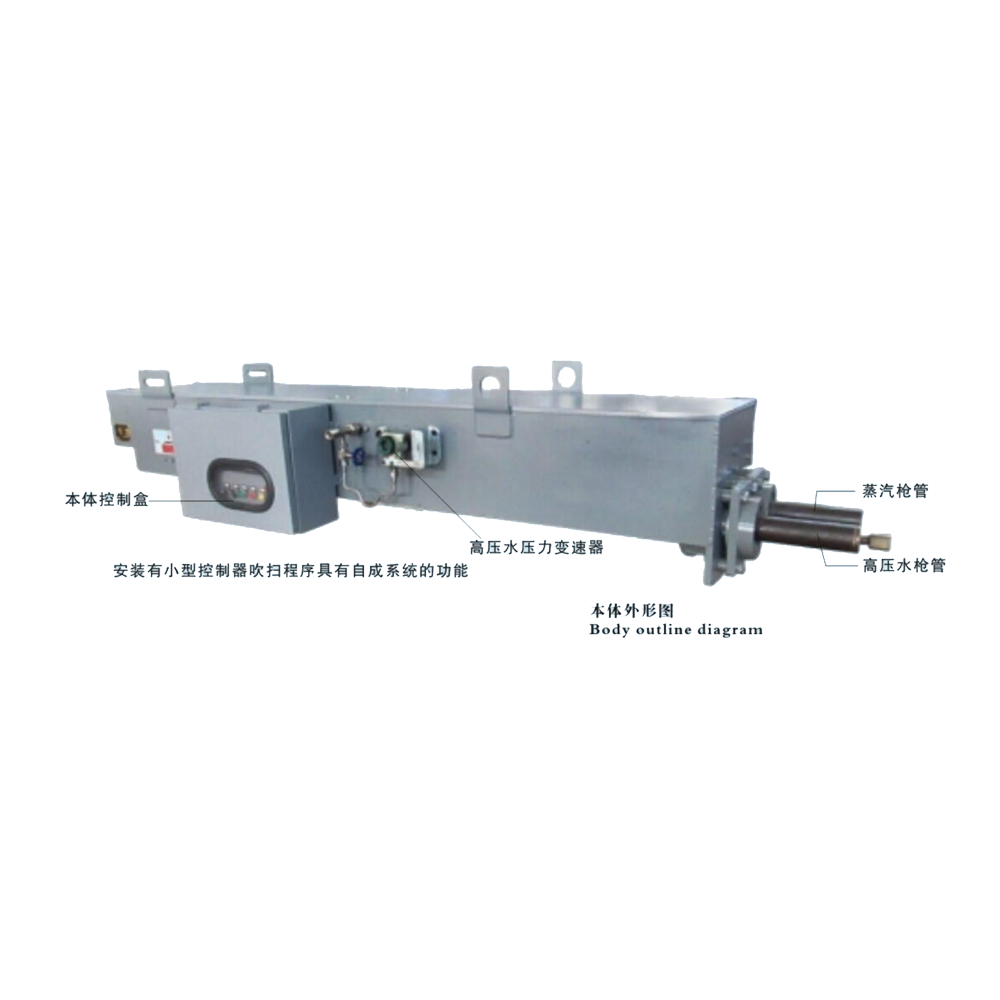

Dual-media soot blower

Working speed: Dual-media soot blower

Working pressure:30Mpa

Request Product details

Zhejiang Liansheng Chemical YQL series 8 million kcal gas-fired thermal oil boiler project

Industry:Chemical Industry Cases

Supporting Products:YQL-9400Q

ConsultationView Details

Export to Morocco: SENTURY SZS series gas steam boiler tire industry project

Industry:Rubber industry case

Supporting Products:SZS10-2.5-Q,SZS15-2.5-Q

ConsultationView DetailsDo you have any further questions?Consultation or direct phone call is available

Huaxing soot blower consultation hotline

+86-724-7223090- 01 Fill in requirements

- 02 Telephone docking

- 03 Scheme customization

We will contact you as soon as possible (strictly protecting your information from leakage, please feel free to fill in)

Manager

Sales Department Network Administrator

Hubei Huaxing Machinery Technology Co., Ltd.

Senior engineer

Senior engineer